- Home Page

- Company Profile

- Our Products

- Contact Us

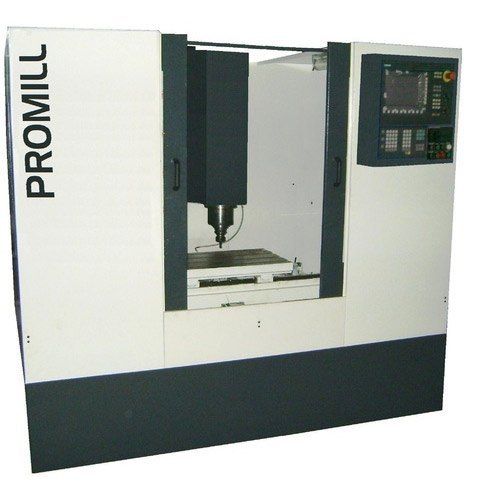

ProMill 850 CNC Milling Machine

1650000.00 INR/Unit

Product Details:

- Product Type ProMill 850 CNC Milling Machine

- General Use Industrial

- Material Metal

- Type Vertical

- Weight (kg) 3000 Kilograms (kg)

- Computerized Yes

- Automatic Yes

- Click to view more

X

ProMill 850 CNC Milling Machine Price And Quantity

- 1000000.00 - 1600000.00 INR/Unit

- 1650000.00 INR/Unit

- 1 Pair

ProMill 850 CNC Milling Machine Product Specifications

- High

- 800*500 mm

- 3000 Kilograms (kg)

- Yes

- 800*500*500 Millimeter (mm)

- one year

- AC Motor

- Industrial

- No

- ProMill 850 CNC Milling Machine

- Electric

- 10 Kilowatt (kW)

- White

- Low Energy Consumption High Speed High Precision

- Metal

- 440 Volt (v)

- No

- 8000 RPM

- Yes

- Vertical

ProMill 850 CNC Milling Machine Trade Information

- NHAVASEVA MUMBAI

- Letter of Credit (L/C) Cash in Advance (CID)

- 2 Pair Per Month

- 8 Week

- Contact us for information regarding our sample policy

- Asia

- All India

Product Description

CNC milling machine is a computer-controlled machine tool used for precision machining operations. It utilizes computer numerical control (CNC) to automatically perform milling processes, where rotary cutting tools remove material from a workpiece to create complex shapes and features. CNC milling machines are widely used in manufacturing and prototyping industries to produce high-precision parts for various applications, offering efficiency, accuracy, and repeatability in the machining process.

Frequently Asked Questions (FAQ):

Q: What does CNC stand for in CNC milling machine?

A: CNC stands for Computer Numerical Control. In a CNC milling machine, a computer system controls the movements of the cutting tools and the workpiece, following precise instructions from a program to create the desired part.

Q: How does a CNC milling machine work?

A: A CNC milling machine operates based on the programmed instructions from a computer. The operator creates a digital design of the part using computer-aided design (CAD) software and converts it into machine instructions (G-codes and M-codes). The CNC milling machine then follows these instructions to move the cutting tools and remove material from the workpiece, creating the desired shape.

Q: What types of materials can a CNC milling machine work with?

A: CNC milling machines can work with a wide range of materials, including metals (such as steel, aluminum, brass, and titanium), plastics, composites, and various types of wood.

Q: What are the advantages of using a CNC milling machine?

A: CNC milling machines offer several advantages, including high precision, accuracy, repeatability, and versatility. They can produce complex parts with tight tolerances and are efficient for both prototyping and large-scale production.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free