- Home Page

- Company Profile

- Our Products

- Contact Us

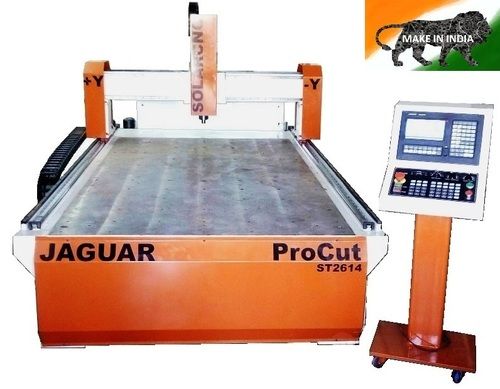

CNC Wood Router

654000 INR/Piece

Product Details:

X

CNC Wood Router Price And Quantity

- 654000 INR/Piece

- 1 Piece

CNC Wood Router Trade Information

- All India

Product Description

With a vision to be a pioneer in our domain and establish ourselves as a brand, we are engaged in manufacturing and supplying excellent quality CNC Wood Router. It is installed in different industries for performing various types of cutting, engraving, designing and other applications. We check these routers on different quality parameters under supervision of experienced quality controllers to ensure its flawlessness. Our machine is operational for different metallic or non-metallic products such as wood, metal, plastic and others. Our product is acclaimed by clients for its numerous features like robust construction, low maintenance needs, easy installation, and prolonged service life.

Frequently Asked Questions:

Q: What is a CNC wood router?

A: A CNC (computer numerical control) wood router is a machine that uses computerized controls to cut, carve, and shape wood. It is a highly precise and efficient tool that is used in woodworking, furniture making, cabinetry, and other related industries.

Q: What are the advantages of using a CNC wood router?

A: CNC wood routers offer many advantages over traditional woodworking methods. They are highly precise and accurate, which means that they can produce intricate designs with a high level of detail. They are also faster and more efficient than manual methods, which means that they can produce large quantities of work in a short amount of time. Additionally, CNC wood routers can be programmed to produce consistent results, which ensures that every piece of work is of the same high quality.

Q: What types of projects can be done with a CNC wood router?

A: CNC wood routers can be used to create a wide variety of projects, including furniture, cabinetry, decorative items, signs, and more. They are capable of cutting, carving, and shaping wood in many different ways, which means that the possibilities are almost endless.

Q: What types of wood can be used with a CNC wood router?

A: CNC wood routers can be used with many different types of wood, including hardwoods, softwoods, plywood, MDF, and more. The specific type of wood that is used will depend on the project requirements, such as the desired finish, durability, and cost.

Q: How do you operate a CNC wood router?

A: CNC wood routers are operated using specialized software that is designed to communicate with the machine. The software is used to create a digital design or pattern, which is then transferred to the machine. The machine uses this information to cut, carve, and shape the wood according to the design.

Q: What safety precautions should be taken when using a CNC wood router?

A: CNC wood routers can be dangerous if not used properly. It is important to follow all safety guidelines and precautions, such as wearing protective eyewear, keeping long hair and loose clothing away from the machine, and ensuring that the machine is properly grounded. Additionally, it is important to keep the work area clean and free of debris, and to never leave the machine unattended while it is in operation.

Q: What is the cost of a CNC wood router?

A: The cost of a CNC wood router can vary widely depending on the size, features, and capabilities of the machine. Entry-level machines can cost as little as a few thousand dollars, while more advanced models can cost tens of thousands of dollars or more. Additionally, there may be additional costs associated with the software, tooling, and maintenance of the machine.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free